Printing

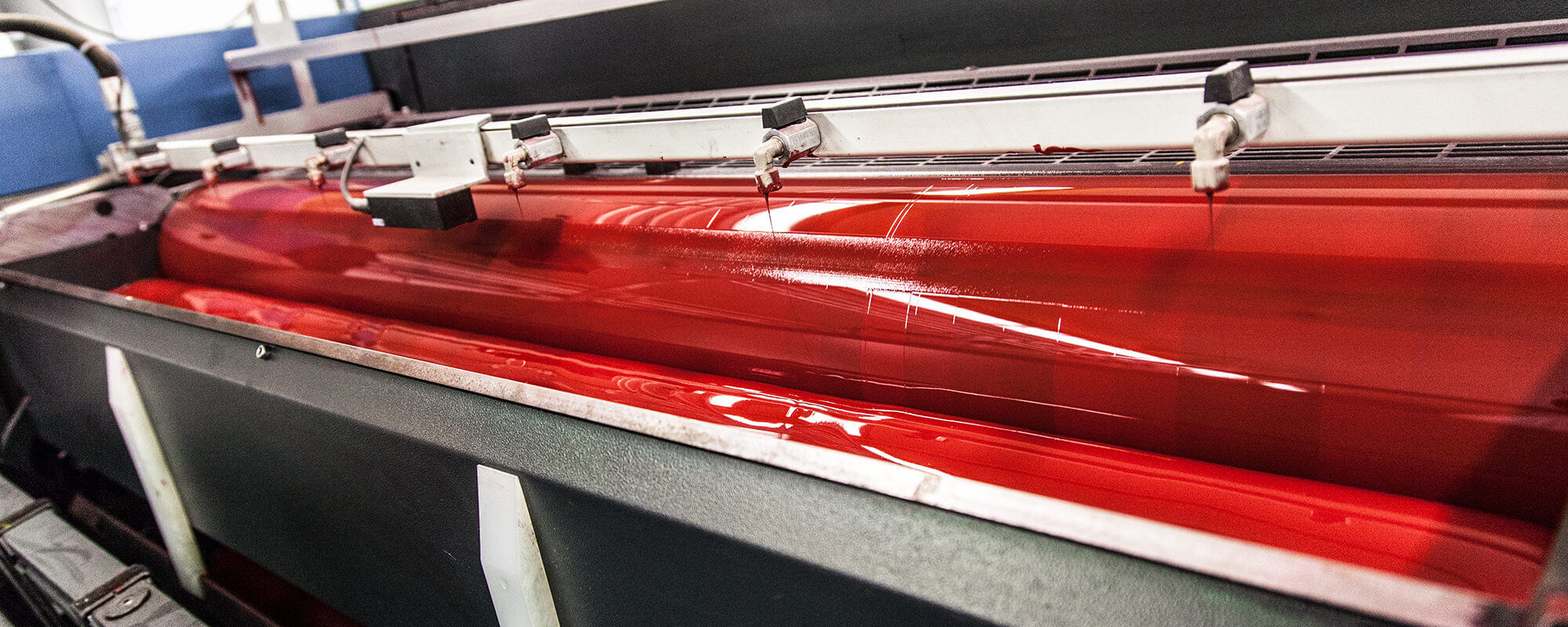

With printing capacity of 300,000 sheets per day and workflows that are precisely defined and with our high-grade printing and varnishing technologies, we turn our back on supply bottlenecks. It is our cutting-edge printing machinery that ensures high register stability, top color consistency and offers a consistent top quality – due to technologies such as the inline-sheet-monitoring - even at high machine speed.

For the printing process, WS Quack + Fischer uses high-grade, mineral-oil free and non-harmful-to-food printing inks from MGA and BeFood MU.

Because of regular laboratory tests and additional inspections of the printing machinery, we leave nothing to chance. here.

Processing

A first-class product deserves a high-class staging.

Our ultra-modern punching machines and special adhesive systems offer your product the wished-for outfit and unique look. Sift-proof packaging, automatic bottoms, hot-foil embossing and relief stamping as well as 4- and 6-point sealing or window insertion and gluing are all WS Quack + Fischer standard.

Quality

The quality demands upon packaging, packaging products and materials and assistive devices are rising. For the protection of packaged goods, a variety of demands regarding storage and transport, declaration and advertising as well as regulations and laws must be met.

The team at WS Quack + Fischer and the machinery and plants are geared to these high requirements.

Every year, audits are carried out at WS Quack + Fischer in order to ensure that our quality management fulfils the requirements for certification according to DIN ISO 9001-2015, BRC/IoP, FSC and PEFC.

BRC-certified

WS Quack+Fischer is BRC-IoP-certified and follows clearly specified standards for suppliers of wrapping for primary food packaging.

FSC® – Chain of custody

WS Quack + Fischer fulfils the requirement to use FSC®-certified products, thus contributing to sustainable forest utilization by the forest industry.

DIN EN ISO 9001

The DIN EN ISO 9001 certification is the basis for the quality management at WS Quack+Fischer and we strictly act according to these specifications.

Contact

We gladly invite you to come and visit our facility where we can present our individual solutions for packaging on-site to you.

For over 110 years we have been placing our knowledge at the service of our customers.